A study published in ACS Applied Materials and Interfaces in April purports to solve a problem that has been plaguing recent attempts to create a stronger carbon fiber.

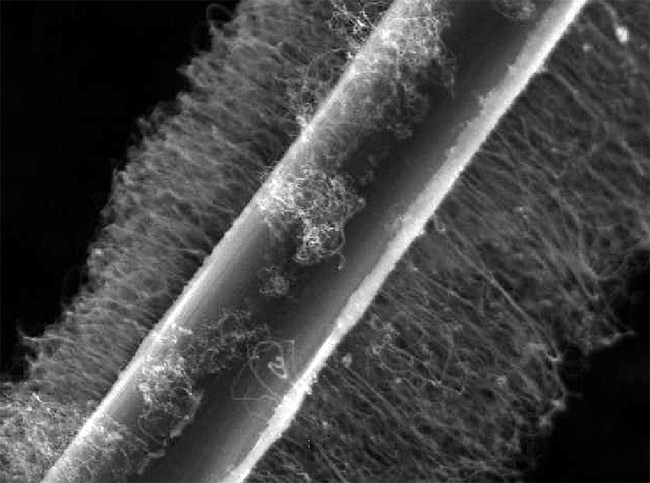

Carbon fiber materials are composites used in aircraft, spacecraft, and cars, that can match the strength of steel and titanium for only a fraction of the weight, reducing the load on a vehicle by 20 percent. Â To make this material even stronger, researchers have been experimenting with coating the fibers with carbon nanotubes. Â These tiny tubes of one-dimensional carbon sheets could increase the strength of the carbon fiber dramatically, but every attempt to grow nanotubes on the fiber has ended up damaging the fiber base and weakening the material.

As reported on the MIT News Office, a team of researchers at MIT has discovered the probable mechanism of this weakening and come up with several methods of successfully coating carbon fiber with carbon nanotubes. Â Their techniques have produced nanotube-coated fibers that do not weaken the underlying material, resulting in a product that is twice as strong and more electrically conductive than previous carbon fiber.

Brian Wardle, associate professor of aeronautics and astronautics at MIT, co-wrote the paper along with postdoc Stephen Steiner and graduate student Richard Li. “Up until now, people were basically improving one part of the material but degrading the underlying fiber, and it was a trade-off, you couldn’t get everything you wanted,” says Wardle. “With this contribution, you can now get everything you want.”

The team found that growing nanotubes will weaken the carbon fiber when the fibers are not held under sufficient tension while being heated, due to a previously undiscovered mechanochemical process. Â They developed two separate techniques to grow nanotubes without weakening the fiber.

The first technique involves coating the fiber with a layer of alumina ceramic, which allows a further coating of an iron growth catalyst to stick to the fiber without degrading it. Â The alumina ceramic is held in place with a novel compound the team developed called K-PSMA, which both sticks to the carbon fiber and attracts the coatings to it. Â This process allowed nanotubes to grow successfully.

The second technique involves growing the nanotubes at a reduced temperature, almost 300 degrees Celsius less than the usual. Â The researchers grew nanotubes successfully at a reduced heat using a new growing method along with the K-PSMA. Â They noted that this process is quite cost effective and simple, compared to traditional methods.

The next steps for this research will be in ensuring that the coatings and nanotubes stay in place when the carbon fiber is put to use.

To read the publication in full, check out the ACS Publications website.