This post was guest blogged by Nicholas Spens. Â Nicholas is a bespoke furniture designer in the UK specializing in using carbon fiber and wood in his designs. Â The pieces below were commission by Sir James Dyson (The same guy who brought you the Dyson vacuums) and is an overview of the design/build process.

The overall brief for the project was to create a series of carbon fiber pieces of furniture that involved coffee tables, dining chairs and sun loungers. All of the furniture was to be used outdoors. Sir James Dyson was looking to have something unique and have the ability to design something from scratch that he drew to his requirements.

After our first meeting, it was clear Sir James had the initial designs he wanted to create, either in sketch form or in ply mock-up’s. We then continued to co-design the pieces together where I explained what composites are capable of and what would be practical for manufacturing purposes before cost became prohibitive.

We concluded the designs and kept a shared aesthetic between all the pieces both in style and form to create a coherence with all the furniture. The overall concept was driven by the aesthetic look of the furniture and the use of carbon being able to create something that conventional materials could not.

This created its own problems. Firstly, the furniture would be lightweight given the structural properties of carbon fiber, and the fact that the carbon was to be visible under a high gloss varnish finish. As the pieces were to be used outdoors, if they were too light, when not being used they simply could blow over with any sort of breeze. To combat this, it was decided to build into the structures of the coffee tables and dining chairs a steel plate in the bases to give them a lower centre of gravity and some overall weight.

Using a 5mm corecell foam core, the steel plate was fitted into a space created in the core before over laminating the outer skins of carbon, therefore hiding the counterweight from view to keep the slim line profile of the pieces uniform and consistent. Because the carbon was to be visible it was imperative to keep the weave pattern of the 300gsm 0-90 twill absolutely straight as it contoured round the shape of the designs without any overlaps or cut lines.

The dining chairs and coffee tables were laminated with single pieces of carbon on both faces to achieve this look, but with the lounger base cut lines and trimming were necessary to build the shape required. Therefore all the cutting points had to be done in places where they would not be visible when completed and varnished.

All the furniture was constructed using a wet lay-up process, vacuuming and post cure heating. I tend to use wet lay-up more than prepreg carbon as the main feature of my furniture for aesthetics rather than structural ability. The loads, for example, in a chair can be easily overcome with minimal use of composites and for the client they really choose carbon because they enjoy the look of the material. I find prepreg gives a rather flat finish whereas a wet lay fabric produces a much greater sense of shape within the weave which when varnished gives a sort of 3D effect that “moves†as you walk around the piece. Something you rarely see in mass produced items.

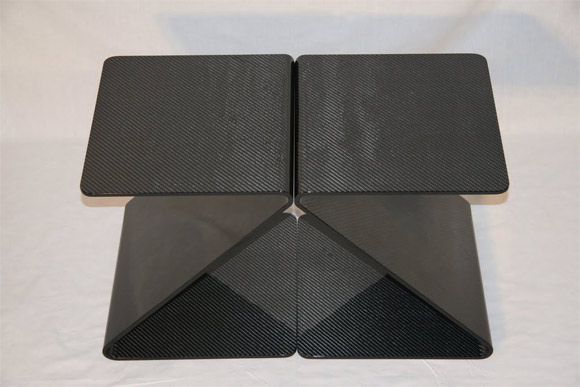

The dining chairs and coffee tables were constructed using the same processes. Given the “Z†profile of the design it was important to create enough stiffness that they could be used without the need for any form of bracing or supports. The idea was for the user to look at them and wonder if something that is only 1cm thick will actually support their weight.

And it does. To achieve this the main component was several layers of 400gsm carbon uni, a +/- 45 biax to aid with twisting issues and the outer 0/90 twill as the visible skins. All this material was laid into the mould as one piece sheets to obtain maximum structural benefit. As said a 5mm corecell foam was used with a very high density core used in the tight radiuses to prevent crushing.

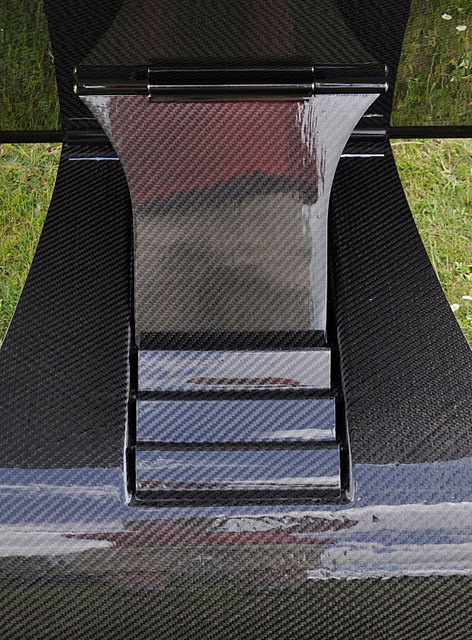

The lounger was created much in the same way. However, as the base had a large channel running down the centre, which housed the hinge mechanisms for the back rest and leg support, this shape created its own required stiffness for the piece. Built into this channel was a section of ply to add some overall weight to the piece to prevent them being blown about.

All the cuts in the carbon were done in this channel which were then covered by the hinge mechanism, which was a separate moulding bonded in after the base had been constructed. The hinge mechanisms were based on a piano hinge using carbon tubing bonded to the seat panels with a stainless steel pin running through them.

The reason for this was to keep the profile as slim as possible and remove the visual issue of screw or bolt heads showing in the varnished carbon. Panels were then bonded to the underside of the seat and back rest using the same process that then locked into triangular slots in the base channel allowing for a lounger that can convert from a completely flat bed to a sit up position and various angles in-between.

All the items were finished with teak feet to prevent abrasion of the floor or the furniture. A high gloss UV resistant acrylic varnish was used to give the pieces maximum protection outdoors, more commonly used on yachts with composite components exposed to the elements.

I hope this covers most of the technical points of the furniture, however if anyone wishes to find out more, please contact me through my website, where there are more pictures as well . These designs are solely owned by Sir James Dyson so cannot be replicated in any way and cannot be reproduced for anyone else. If anybody has a concept, or wishes to have their ideas turned into a reality, I would be happy to discuss those concepts with them and suggest any issues with the use of carbon fiber, and of course an idea of cost to make their designs a reality. I am equally happy to draw something for a client and then guide them through the design process to create something that they want that is individual to them.