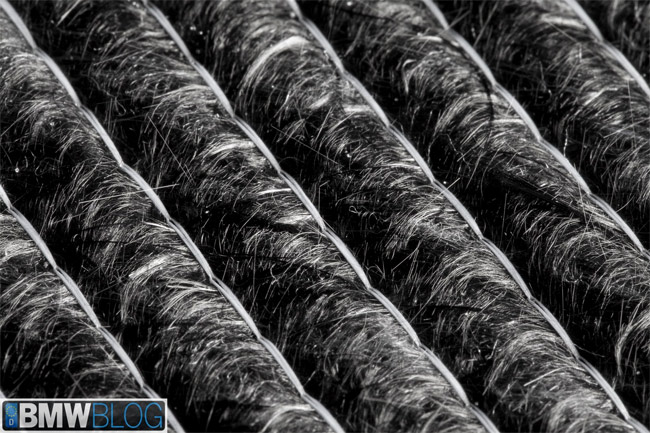

Sculptures. Moon boots. Shoulder pads. High-priced cameras. If you’ve been visiting the site over the last few months, then you know all about the growing interest in carbon fiber. And now, thanks to MAI Carbon Cluster Management GmbH, a research entity backed by the German federal government and its research institutions, that increasing interest is likely to ascend into an all out obsession.

Backed by a $102 million budget, provided by over 70 companies and other entities — BMW, Audi, Siemens and SGL Carbon to name a few — MAI is taking aim at reducing carbon fiber production costs by as much as 90 percent.

For reference, carbon fiber currently costs about $20 for a single kilogram (2.2 pounds) in raw form, as apposed to $1 for steel, which is much, much heavier.

And, according to Klaus Drechsler, head of MAI, they’re already well on their way to reaching that goal. “We’ve certainly reached a halfway point on our cost-cutting target for suitable carbon-fiber parts,” he says. “We’ll see a lot more carbon-fiber use in the next generation of cars.”

That generation that already includes BMW’s i3 electric city car and their i8 hybrid sports car, both of which use carbon fiber in their passenger frames, and the former of which sold more than 10,000 models in the first nine months of the year — further showcasing the desire consumers have for light and fuel-efficient automobiles, attributes that carbon fiber allows for.

Cars are only a jumping off point of course. As we’ve seen with steel and other such materials, it only takes a single, multi-billion dollar industry to invest, innovate and to bring down production costs overtime.

In fact, if we wanted a true representation of what carbon fiber will actually look like in the near future, Junus Khan, founder of Carbitex, would have us look at another, more ubiquitous metal.

“I believe the history of aluminum is a good illustration of carbon fiber’s future,” he says. “Aluminum was once more expensive and exclusive than gold. For some context, Napoleon had an aluminum utensil set while gold was reserved for his guests.”

Junus goes on to cite innovations in mining, extraction and production as reasons why it has since bloomed into the everyday item we know it to be.

“Carbon fiber has gone from aerospace and military applications to F1, to high-end automotive, to premium products,” he continues, now comparing it to our all-time favorite composite. “And over time it will [become] a main staple material like aluminum. This won’t happen over night, but perhaps within 15 years.”

We’re hoping sooner. And we’re sure that Klaus Drechsler and the backers of MAI are hoping for the same as well.

[Sources: Automotive News, BMW Blog (photos)]