When we found out one of our partners made a custom Ford emblem with carbon fiber and orange Kevlar, we had to ask if he could put together a little behind-the-scenes article for us. Â We thought it would be something you guys would be interested in seeing how something like this is done. Â Here’s what we’ll be making:

Here’s a step-by-step that shows how it went from nothing to something:

Busted Ford emblem that needed some bondo work to use as a mold to make custom emblems:

Getting the right size pieces of Kevlar cut. Kevlar is very hard to cut and requires special scissors and the tape keeps the weave from distorting:

Wet laying orange Kevlar. The white tape on the edges keeps the weave from distorting, it is later trimmed off:

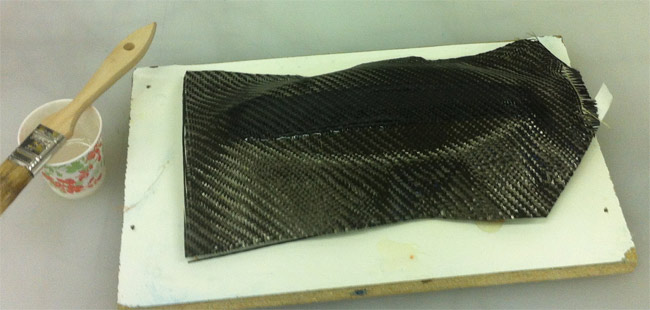

After the Kevlar was cured and removed. The same was done with carbon fiber:

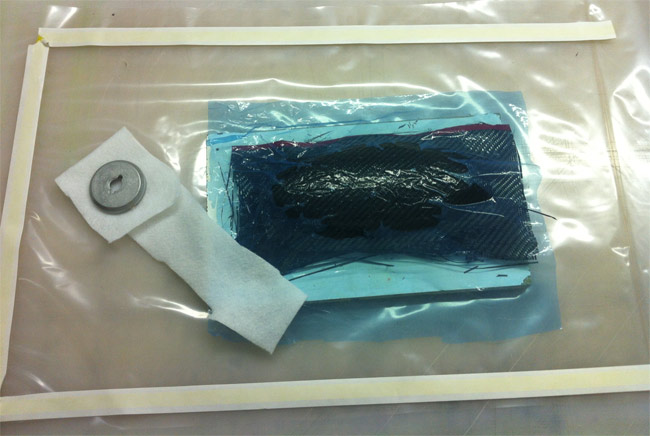

Here I setup vacuum bagging and this is before vacuum is applied:

Enveloping and vacuum bagging ensures a perfect molded part without air bubbles:

Using wax on the mold, left an outline of the relief pattern so the ring and Ford lettering could be cut out:

Here’s a rough cut out. Next was hours spent hand sanding and filing to get the shapes right:

The Ford lettering was waxed and set in bondo so that the outline of the lettering could be cut out without it moving around:

Here are the two materials cut out and coming together:

The first steps of building up the clear coat. I decided to build up and have a smooth finish, however letting the relief show though would have been pretty sweet too!

Close up on the detail with the final smooth finish:

Here it is on the truck, however the pics don’t do it justice, it’s much better in person 🙂