This post was guest blogged by Brett Levine of False Profit Labs. To learn more about the carbon fiber garden product, visit the False Profit Labs blog, follow them on Twitter, and check out their Facebook page.

Carbon Fiber Gear Series

CFGear readers are obviously a bunch well-versed in the ways of incredibly well-designed, ultra chic, sleek, innovative carbon fiber products. Well, we’re not there yet. This is the first of three guest blog posts, where we will take you along with us through the trials of amateur carbon fiber part production. We’ll show you the lay-ups and the mess-ups, and meander our way through the complex set of fiberglass mold materials, polyester and epoxy resins, the curing process, and assembly. And finally, we hope, introduce our carbon fiber flower garden of fire, debuting this August 31 at Burning Man.

About False Profit Labs

False Profit Labs is a ragtag team of artists, scientists, engineers, and software geeks that make large-scale fire sculptures out of exotic materials like carbon fiber. In the past few years we’ve built projects like The Hydrogen Economy, a 16-foot-tall polycarbonate plastic chamber. Inside, bubbles filled with hydrogen, oxygen and propane gas float upward which people then get to explode using ignition rods. If you’ve been out to Burning Man in Nevada’s Black Rock Desert or to San Francisco Bay Area fire festivals at The Crucible, Maker’s Faire, or Yuri’s Night at NASA, you may have seen our work.

Me, I’m Brett Levine, and call myself an artist and Creative Director of False Profit Labs, as long as I’m not building fire installations for my new company LiveSpark. The Hydrogen Economy is my baby, though no project in our group could ever be said to belong to fewer than twenty people who really make it happen.

Hydrogen bubbles explode inside our polycarbonate chamber.

Our motto is “Better Art Through Science”, and we take it seriously, as seriously as we take anything I suppose. The Experimental Approach to life is culturally our most common thread– that and enjoyment of building pretty things that blow up. DTFE is commonly exclaimed around our shop: Do The F*ing Experiment! I also like the term vu jadé. If deja vu means seeing something new again, vu jadé would be seeing familiar things in a new light. To Reinvent. To Re imagine.

So we reimagined that boring old pulse meter from the doctor’s office. PyroCardium, envisioned by Dr. Kurt Thorn, a microscopy expert who works at the Nikon Imaging Center on the famed UCSF Mission Bay campus where they’re, you know, “using fluorescent tagging to understand and predict the morphology of cancer cells.”

PyroCardium is made of 40 flame pipes, each 10 feet tall, arranged in a 20-foot circle around a person standing at its center. The victim, er participant, attaches a pulse oximeter (heartbeat monitor) to their finger, and with each palpitation, three-foot-long flames sequentially burst from the pipes in rhythmic patterns around the circle. PyroCardium will appear at the Coachella music festival in Southern California from April 17-19.

Pyrocardium shows heartbeats of fire

This year we received our largest ever art grant from Burning Man to build a project we call Carbon Garden. Our vision is to create a peaceful flower garden, built out of carbon fiber. Each flower will stand 3-4 feet tall and will contain one of our computer controlled flame effects. Glistening, opalescent carbon fiber, gleaning black and dead in the brightest sun, then bursting into flames of life and music in the dark of night. It is this elemental purity, strength, and of course that beautiful gridded carbon fiber aesthetic that drives the vision of Carbon Garden.

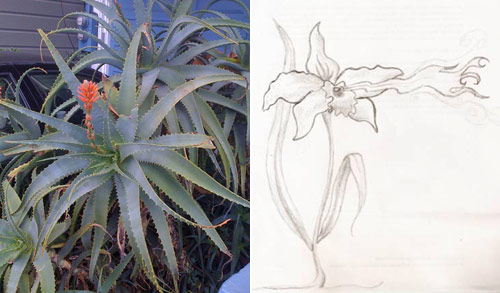

A model flower. Imagine the bloom in flame.   Artist rendering of fire bloom.

How To Make Flat Things

This may be familiar territory for some of you, but let’s start with carbon fiber cloth. It comes on rolls just like any other fabric. In San Francisco you can drive over to TAP Plastics and buy it for 50 bucks per yard, 50 inches wide. It’s floppy, a little stiff (you wouldn’t want to wear it), but of course it has that sexy black grid pattern. Like other fabrics, CF comes in a variety of weaves, and depending on the shapes you’re creating with it, you can pick a plain rectangular weave, twill (zigzag weave), or other artistic weaves. But let’s stick with the plain weave for now and for our first experiment just try to make a one-layer flat sheet.

If you’ve worked with fiberglass, carbon fiber is very similar. First you mix up a batch of epoxy. Epoxy is a binary resin, that stiffens the carbon fiber to hold a set shape. In our case we used TAP Plastic’s Marine Grade Epoxy A-Side resin and Medium B-Side Hardener, which is mixed in a four to one ratio. You have to wear gloves since epoxy is toxic and bio-accumulative, meaning you’ll be having loads of fun until one day it’s time to go to the hospital.

Next we spray a piece of clear mylar with Pol-Ease release agent (could also use pure carnuba wax) to prevent the epoxy from sticking. Then we apply the epoxy to the sheet of carbon fiber with a paintbrush and a plastic squeegee. More release agent and another sheet of mylar to make a sandwich, and that’s it. We press the mylar between two blocks of wood, clamp it and stick it in a regular oven for 25 minutes at 175 degrees. When it’s done, pull it apart, and voila: a beautiful, shiny sheet of carbon fiber.

Carbon fiber fabric and our finished sheet.

No room in the workshop, so we bought an oven on Craig’s List and stuck it in my back yard.

On To Curvy Things

A great deal more challenge comes when you’re trying to make a curvy shape. Especially the one that you intended. We’re working with Sara Chieco, an amazing clay sculpture artist who has begun sculpting leaves and petals, then glazing and firing them. These are our “positives”, so-called because like a photograph, this is what we want to copy in the end. We then create a fiberglass “negative”, in which we can layup the carbon fiber. We haven’t actually done this part yet, but the TV Show “How It’s Made” has a great example that shows the process on a carbon fiber cello.

Sara at the pottery wheel.

The ceramic and carbon fiber leaves.

So far we have made a sample by laying the carbon fiber on the ceramic leaf. And the shape comes out smooth and uniform. We’re on our way to building the parts for a flower. Next post, we’ll be vacuum bagging, optimizing our epoxy, and introducing an opalescent pigment for a pearly glint in the sunlight.

To learn more about the Carbon Garden project, visit the False Profit Labs blog. You can also follow us on Twitter and join us on Facebook. Don’t forget, this is part of a three-part series here on Carbon Fiber Gear, so make sure to stay tuned for the next part! We’d be glad to hear your ideas and advice, so get involved!

Until next time, this is Brett Levine, your friendly neighborhood fire artist signing off.